Ensuring product quality in large-scale packaging production requires rigorous monitoring, continuous improvement, and cross-departmental collaboration to ensure optimal results. The GH6581 Packaging Box Abnormality Analysis Report documents the issue encountered, the corrective measures taken, and the lessons learned by YUTO Technology in its commitment to quality assurance.

To tackle the issue, a cross-functional improvement team was formed, bringing together expertise from marketing, quality, production, engineering, and PMC departments.

|

Name |

Department |

Position |

Remark |

|

Huang Yanrong |

Marketing Dept. |

Deputy Manager, Business |

|

|

Cao Xu |

Quality Dept. |

Quality Manager |

|

|

Fang Yan |

Quality Dept. |

Section Chief, Quality |

|

|

Gan Yonghong |

Production Dept. |

Production Manager |

|

|

Ren Jinna |

Quality Dept. |

QC Team Leader |

|

|

Huang Bijun |

Quality Dept. |

QE Engineer |

|

|

Zhang Tiesheng |

Production Dept. |

Deputy Manager, Production |

|

|

Li Pingjiang |

Engineering Dept. |

Deputy Manager, Engineering |

|

|

Li Xiulan |

PMC |

Order Follower |

|

|

Zhang Gang |

Production Dept. |

Section Chief, PE |

|

|

Zhang Dahua |

Production Dept. |

Section Chief, Production |

A detailed review of the abnormality identified in the GH6581 Packaging Box project is summarized below.

|

Item |

Details |

|

Occurrence Date |

2024.08.07 |

|

Material Part Number |

286729826 |

|

Occurrence Location |

Maidu |

|

Defect Rate |

60% |

|

Project Name |

GH6581 Packaging Box |

|

Material Production Site |

Suzhou YUTO |

|

Project Stage |

■ Mass Production |

|

Abnormal Process Stage |

■ IQC |

|

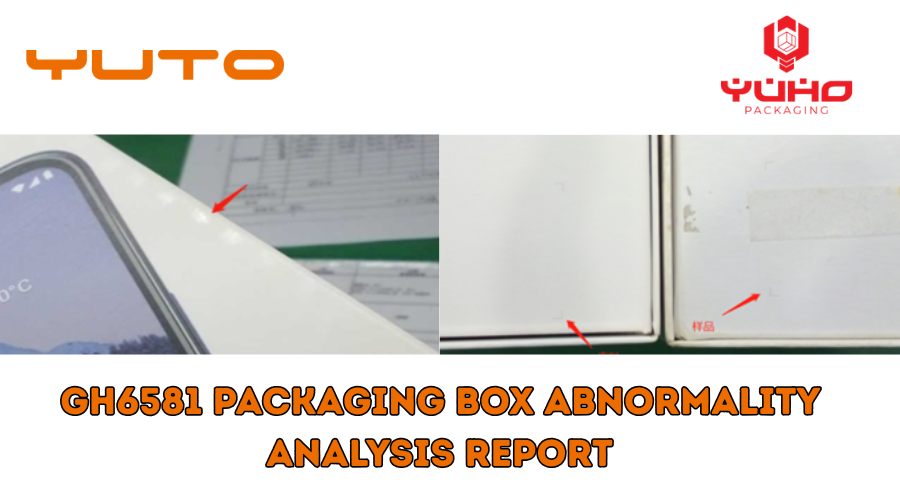

Abnormal Issue Description |

On 2023.03.21, Maidu IQC reported GH6581 packaging box (Part No: 286729826), incoming quantity 1040 pcs, with a defect rate of 60%. Main defects included glossy print on the box sleeve and misaligned corner lines on the inner box. |

Immediate containment measures were taken to isolate and rework defective units while minimizing client impact.

|

Location |

Q’ty |

How to Deal With |

Result |

Date |

Remark |

|

Internal In-Process |

- |

- |

- |

- |

- |

|

Internal Inventory |

800 pcs |

Isolated & Reworked |

- |

08/09 |

- |

|

In Transit |

- |

- |

- |

- |

- |

|

Client In-Process |

- |

- |

- |

- |

- |

|

Client Inventory |

1040 pcs |

On-site rework arranged |

Rework completed |

08/09 |

- |

The packaging production process involves several steps. The following stages were identified as defective processes:

Inner Box Die-cutting and Waste Removal

Inner Box Gluing and Forming

Assembly and Full Inspection

Packing

Shipment

Root Cause: During the corrugated paper mounting process of the inner box, misalignment occurred. Although the die-cutting machine was adjusted correctly, defective products were mixed with good ones and defects appeared after cutting.

Outflow Reason: Assembly workers overlooked the misalignment, and final inspection along with OQC failed to detect the issue, leading to shipment of defective products.

Root Cause: Friction between the box sleeve surface and copy paper during transportation resulted in glossy marks.

Outflow Reason: Neither final inspection nor OQC identified the glossy print defects, which were subsequently delivered to the client.

YUTO Technology implemented immediate and long-term improvement measures to eliminate recurrence.

|

No. |

Improvement Action |

Execution Date |

Responsible (DRI/ETA) |

Remark |

|

1 |

Train machine leaders and operators to ensure consistency in size, position, and direction during corrugated mounting. On-site inspectors to strengthen sampling checks. |

08.08 |

Zhang Dahua |

Completed |

|

2 |

Require 100% inspection of inner box corrugated semi-finished products before assembly. |

08.08 |

Zhang Dahua |

Completed |

|

3 |

Evaluate adding a PE bag per product to reduce friction. Adjust outer carton size slightly to reduce shaking during transport. |

08.08 |

Zhang Dahua / Ren Jinna |

Completed |

|

4 |

Conduct meeting to communicate client feedback. Train assembly personnel on glossy print and corner misalignment defects. |

08.08 |

Tan Sizai |

Completed |

The GH6581 Packaging Box Abnormality Analysis demonstrates the importance of robust IQC, final inspection, and preventive packaging design. Through targeted training, enhanced inspection procedures, and packaging adjustments, YUTO Technology successfully contained the issue and prevented further client impact.

This case reinforces the company’s commitment to continuous improvement, customer satisfaction, and zero-defect delivery in the packaging industry.