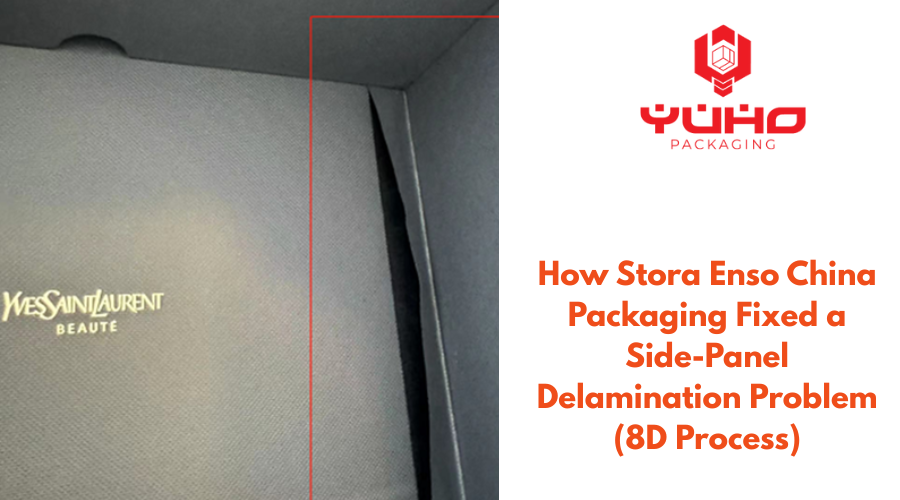

When a premium packaging run for the YSL International Edition — mid-size (YSL国际版中款) reported 15 defects out of 8,300 units (0.1%), the Stora Enso China Packaging team launched a formal 8D investigation. The defect — side-panel adhesive failure during forming/assembly — threatened product quality and customer trust. This post summarizes the 8D approach they used, the root causes uncovered, the corrective & preventive steps taken, and lessons other packaging operations can adopt.

Product: YSL International Edition — mid-size

Order quantity: 8,300 units

Complaint quantity: 15 units (0.1% defect rate)

Production date: July 17, 2024

Reported: July 17, 2024 — 8D opened and planned submission on July 19, 2024

The defect manifested as the side panel “opening” (side panel delamination/adhesive failure) after assembly and forming, which is critical for luxury packaging where both appearance and structural integrity are important.

A containment action was executed, involving the rework/repair of affected units, as well as the replacement (replenishment) of parts that could not be repaired.

The quality supervisor performed the follow-up and completed containment on July 18, 2024.

Containment prevented additional customer returns while investigations proceeded.

A cross-functional team was formed, comprising production, quality, and engineering leaders, to ensure that technical, process, and personnel issues were addressed collectively.

|

Name |

Position |

Department |

|

Yang Jinlian |

Production Supervisor |

Production Department |

|

Wang Chunmao |

Quality Supervisor |

Quality Department |

|

Xu Lin |

Process Manager |

Engineering Department |

Detailed analysis showed a process-level fault during side-panel production:

During specific concentrated time periods the forming equipment experienced intermittent pressure loss, which produced bubbles (air pockets) and left the adhesive in a “pseudo-sticky” condition (superficial tack but weak bonding).

After assembly — where spot hot-melt adhesive was applied — and subsequent forming, those weakly bonded areas would separate (the product “opened”).

In short: transient equipment pressure loss → trapped bubbles / weak glue contact → weak/false adhesion that failed during forming/assembly.

Rework and repair of affected inventory; unrecoverable parts were immediately replaced.

On-site briefings and training were conducted to inform operators and supervisors of the complaint details and handling requirements.

These actions were assigned to production leadership and executed within one to two days of identification.

The team implemented several robust preventive controls:

Design/process tolerance change: the forming insertion tongue (tab) length was fixed at 80 mm. The clearance (gap) around the tab was increased by 10 mm on each side (total clearance of 100 mm), centered, which reduces the mechanical stress that can pry an imperfect glue joint open during forming.

Increased online testing frequency: shop floor inspectors now perform forming test checks frequently, with a minimum of 20 forming tests per hour.

Assembly handling control & training: Ensure untreated surfaces face upward during line flow. Change stacking and handling methods (code-board placement, correct operator handling: no dragging or rubbing). Operators received hands-on training.

Cleaner, stricter cleanliness & PPE rules: Inspection and repair staff must use lint-free cloths with defined replacement/cleaning intervals (clean/replace every 1–2 hours as specified). All handlers must wear gloves; no bare-hand contact with finished surfaces is allowed.

These measures address both the mechanical/design side of the product and human/process hygiene that affect adhesion.

Quality and plant management reviewed and approved the actions. The quality department required the incident be documented as a quality case and incorporated into quality control checkpoints; a manager or above will track verification.

Initial verifications were recorded as “closed” administratively, but all items remain subject to follow-up verification on ongoing production runs to confirm effectiveness under real production conditions.

Fast containment limited customer impact.

Root-cause focus on intermittent equipment behavior (not just “bad glue”) enabled robust corrective design and testing changes.

Combining design, process checks, and human factors (training, PPE, cleaning) produced a layered defense against recurrence.

Minimum verification targets (e.g., 20 forming tests/hour) and stricter cleaning/handling rules create measurable KPIs for future audits.

Implement automated pressure/flow monitoring and alarms on forming equipment to catch transient events.

Add a small sampling plan and record for the 20pcs/hr forming tests so trends are easily visible.

Create a bilingual (EN/CN) quick reference sheet for operators describing the handling rules and tab/clearance specs.

Schedule a follow-up 30- and 90-day effectiveness review to verify preventive measures under different shifts and production loads.